ST2 is a chemical tanker intended to transport products requiring significant preventive measures. Accordingly, a type 1 ship should survive the most severe standard of damage stability and its cargo tanks should be located at the maximum prescribed distance onboard from the shell plating.

ST1 is a chemical tanker intended to transport most dangerous products, which require maximum preventive measures to preclude an escape of such cargo.

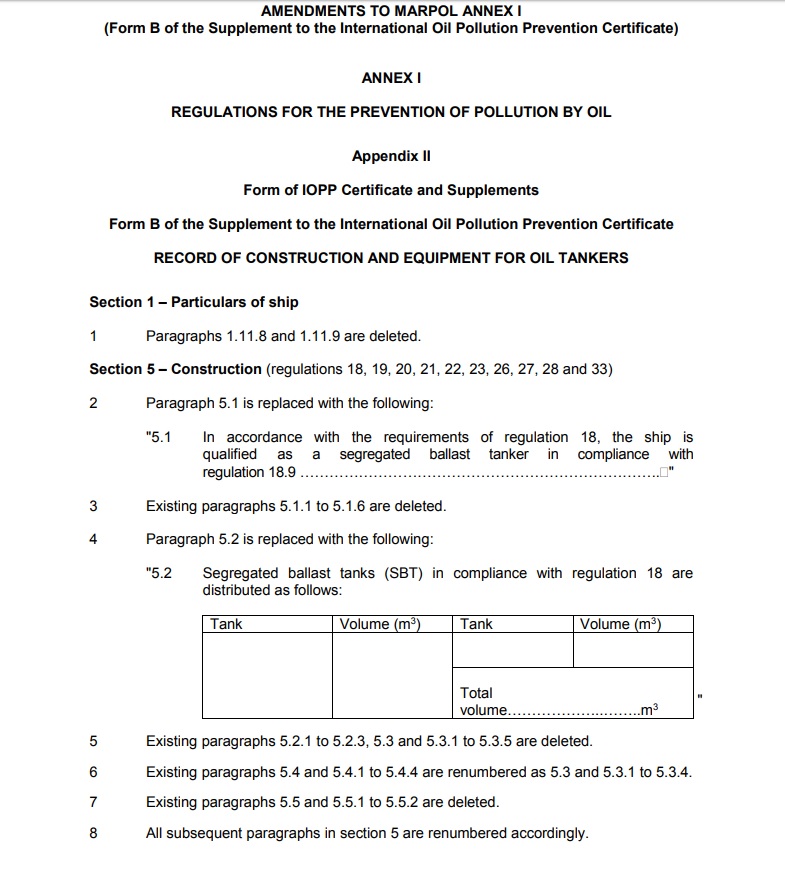

IMO CERTIFICATION REQUIREMENTS CODE

The IBC Code defines three ship types (ST) of chemical tankers: ST1, ST2, and ST3. The coating or cargo tank material determines what types of cargo a particular tank can carry: stainless steel tanks are required for aggressive acid cargoes such as sulfuric and phosphoric acid, while ‘easier’ cargoes - such as vegetable oil - can be carried in epoxy coated tanks.Ģnd – How many types of Chemical substances that designing type of vessel?Ĭhemical cargoes can be very dangerous, most of them being flammable and/or toxic, some of them extremely so.

IMO CERTIFICATION REQUIREMENTS SERIES

Oceangoing chemical tankers ranging from 5,000 to 59,000 DWT in size, which is smaller than the average size of other tanker types due to the specialized nature of their cargo and the size restrictions of the port terminals where they call to load and discharge.Ĭhemical tankers normally have a series of separate cargo tanks that are either coated with specialized coatings such as phenolic epoxy or zinc paint or made from stainless steel. Chemical tankers are required to comply with the various safety aspects detailed in Part B of SOLAS Chapter VIII but are additionally required to comply with the mandatory International Bulk Chemical Code (IBC Code).Īs well as industrial chemicals and clean petroleum products, such ships also often carry other types of sensitive cargo which require a high standard of tank cleanings, such as palm oil, vegetable oils, tallow, caustic soda, and methanol.

However, for ease, the secretariat has also put together a marked up, consolidated text of the revised Regulation 19, as it will stand from 1 January 2015. The changes to the IMO requirements were introduced by Resolution MSC.350(92), which also included changes for passenger ship drills (the enclosed space entry requirements are in paragraphs 2, 4, 5 and 6 on pages 2 and 3). Members should ensure their company procedures reflect the new IMO requirements. The drills and instruction should take into account the IMO guidance on enclosed space entry – Revised Recommendations for entering enclosed spaces aboard ships ( Resolution A.1050(27)) – see IMO Revised Recommendations for Entering Enclosed Spaces Aboard Ships. In addition, all crew members must be instructed on the risks associated with, and procedures for safe entry into, enclosed spaces.

0 kommentar(er)

0 kommentar(er)